Advanced Tank Monitoring with neatMon

Published: 8/19/2024, 7:00:00 AM

The Importance of Leak Detection

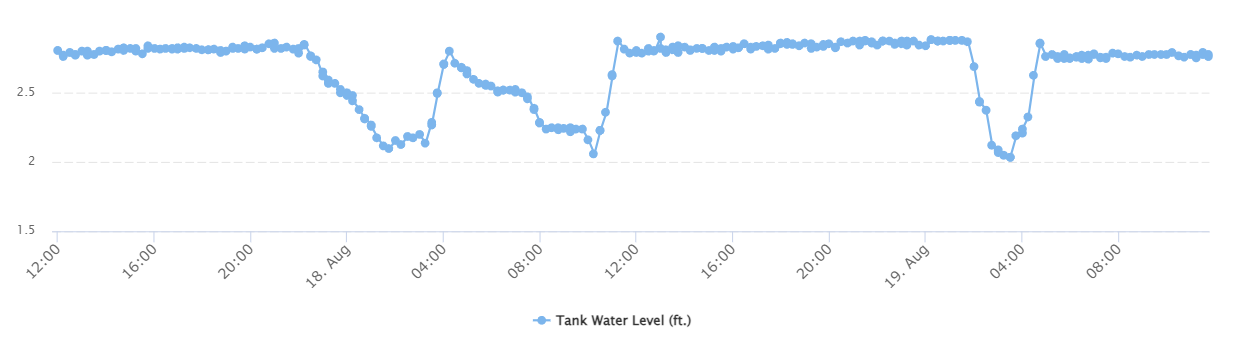

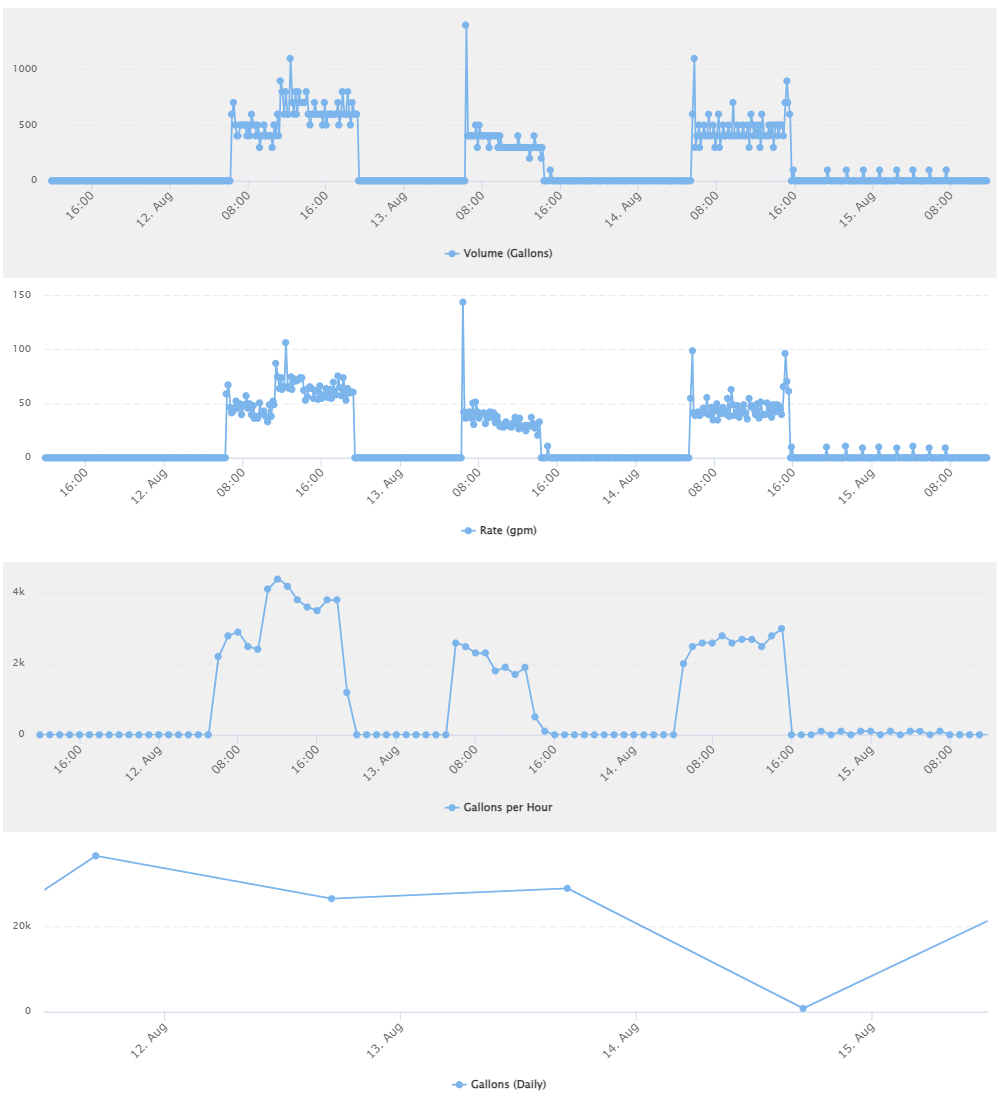

Leaks in tanks holding water, fertilizers, or diesel can lead to significant losses and environmental damage. For example, undetected leaks in water tanks can cause water wastage, nutrient loss, soil contamination, groundwater, or air contamination. Timely leak detection and alerting are therefore crucial.

Contact us to find out more about the neatMon Automated Monitoring Nodes and Cloud Platform

Using advanced sensors, neatMon’s automated monitoring nodes provide real-time data on tank conditions. These sensors monitor fluid levels continuously and detect inconsistencies that might indicate a leak. If a leak is suspected, the system triggers alerts, allowing immediate action. This proactive approach minimizes resource loss and environmental impact, ensuring operations remain sustainable and cost-effective.

Automated Valve Control

neatMon’s system also provides valve control solutions, allowing users or the automated control system to respond to detected issues. For instance, if a leak is detected, the system can automatically shut off valves to prevent further loss. This automation conserves time, reduces manual intervention, and ensures an immediate response, minimizing potential damage.

See our post here about automated valve control solutions

Automated valve control also optimizes the distribution of water and fertilizers. By ensuring resources are delivered precisely where and when needed, neatMon enhances efficiency, particularly in large-scale operations where manual control may be impractical.

The Role of Sensors

The effectiveness of the neatMon system relies on high-quality sensors. The primary sensors used are transducers and ultrasonic sensors, each serving specific monitoring functions.

Transducers: These sensors convert physical quantities, like pressure and fluid levels, into readable signals. They provide accurate measurements of fluid levels, helping detect slow leaks that may not be immediately noticeable but can accumulate over time.

Ultrasonic Sensors: These sensors use sound waves to measure distances and detect objects. In tank monitoring, they effectively measure liquid levels, even in challenging conditions. Ultrasonic sensors are ideal for non-invasive tracking of hazardous or sensitive materials, such as certain fertilizers or diesel.

These sensors provide comprehensive tank monitoring, with data available for real-time use and historical analysis, supporting predictive maintenance and resource planning.

See our product catalog for hardware solutions

Flexibility with Existing Sensors

Recognizing the diversity of needs in agricultural and industrial settings, neatMon automated monitoring nodes are built on an open platform, allowing integration with virtually any sensor. This flexibility means customers can connect their existing sensors to the neatMon system, ensuring seamless compatibility and enhanced functionality tailored to specific operational requirements.

Diesel Monitoring

neatMon systems are also effective for monitoring diesel levels in storage tanks. Diesel is vital in many agricultural and industrial operations, powering machinery and generators. Monitoring diesel levels helps prevent shortages, optimize fuel usage, and detect potential leaks that could lead to environmental hazards. neatMon ensures that diesel supplies are secure and efficiently managed.

Conclusion and Next Steps

Prompt leak detection and automated response are invaluable for those managing water, fertilizers, or diesel. neatMon’s use of high-quality transducers and ultrasonic sensors guarantees accurate, reliable monitoring, making it an essential tool for modern resource management.

Please contact us to find out more about the neatMon Automated Monitoring Nodes and Cloud Platform